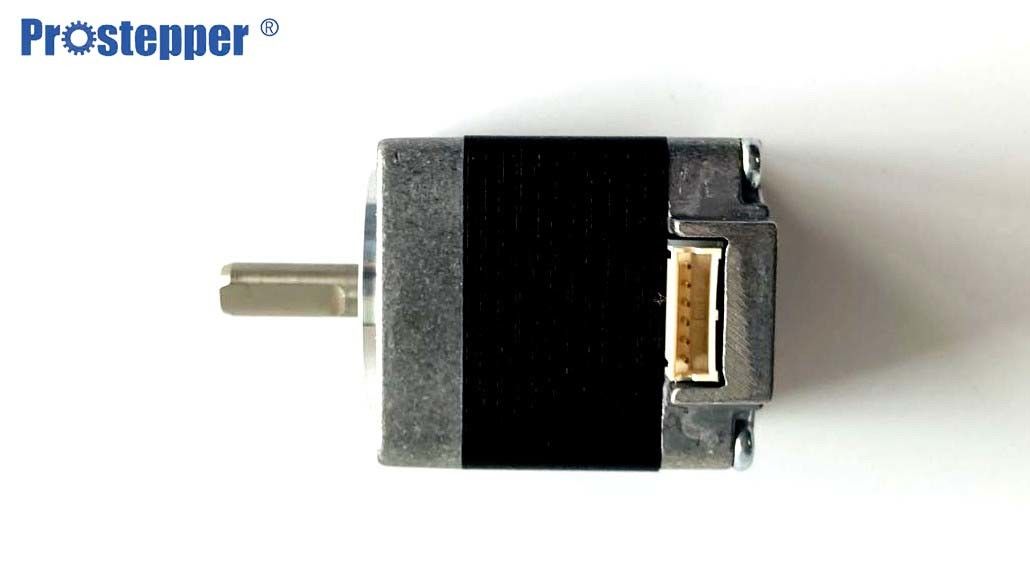

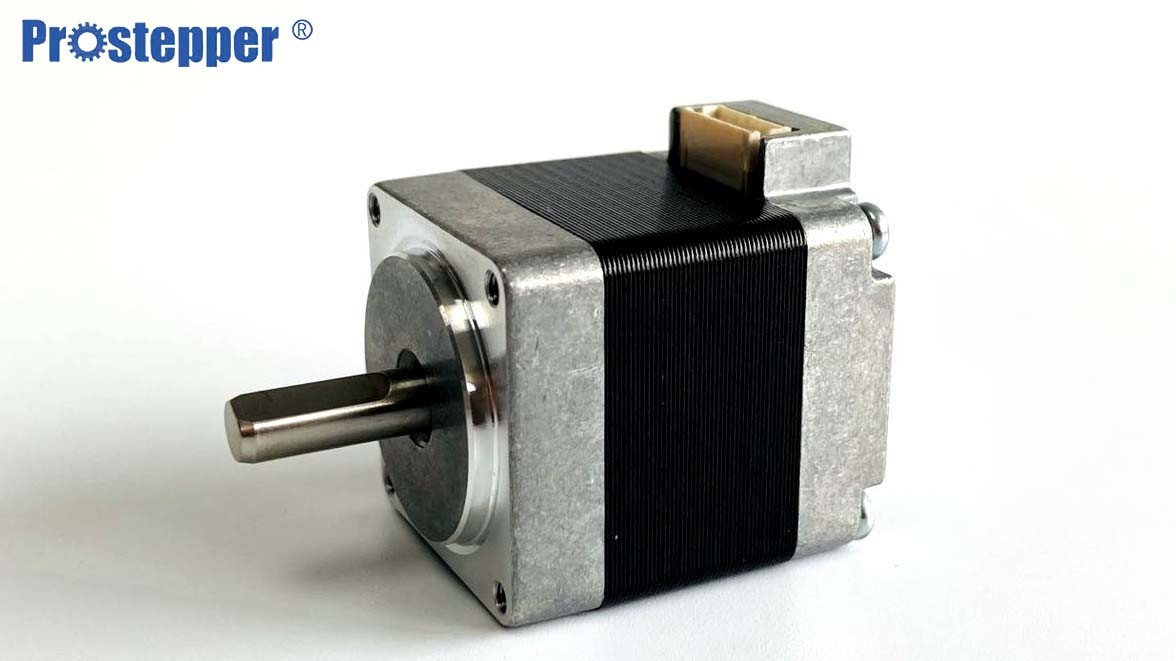

35mm 2 phase stepper motor 1.8 degree hybrid linear stepper motor NEMA14 Bi-Polar

Product description of hybrid linear stepper motor

1. Accurate position Control

The angular displacement of the stepping motor can be precise controlled by the number of electrical pulses.Angle accuracy can be controlled within ±0.09°without any feedback devices.

2. Automatic assembly line

Automatic assembly line, improve production efficiency, low cost without human operation, one line down intelligent mechanical automatic assembly

3. Forward/Reverse Rotation,Pause and Hold

The forward /reverse rotation of the stepping motor can be controlled by the input sequence of the controlled electric pulses.

In the case of the a stepping motor lock(the motor winding is energized,there is no external electric pulse command),the stepping motor can still maintain a certain torque output.

4. Material quality: The coat is 304 stainless steel, the water jacket is the high compression casting aluminum tube, the red copper coil.

Specifications

| Mode No |

PST35H226-6P12 |

PST35H236-6P12

|

PST35H253-6P12 |

| Holding Torque |

0.07N.m |

0.12N.m |

0.25N.m |

| Related Current |

1.2A/Phase |

1.2A/Phase |

1.2A/Phase |

| Resistance |

3.5Ω /Phase |

3.1Ω /Phase |

4.8Ω /Phase |

| Inductance |

1.2MH/Phase |

1.6MH/Phase |

3.2MH/Phase |

| Inertia |

12g.cm2 |

20g.cm2 |

35g.cm2 |

| Weight |

0.15kgs |

0.21kgs |

0.24kgs |

| Length |

53mm |

35mm |

53mm |

| Connection |

P |

P |

P |

| Mode No |

PST35H236-4P10 |

PST35H236-4P15

|

PST35H253-4P15

|

| Holding Torque |

0.18N.m |

0.18N.m |

0.31N.m |

| Related Current |

1A/Phase |

1.5A/Phase |

1.5A/Phase |

| Resistance |

4.6Ω /Phase |

2.1Ω /Phase |

3.25Ω /Phase |

| Inductance |

5MH/Phase |

2.1MH/Phase |

4.1MH/Phase |

| Inertia |

20g.cm2 |

20g.cm2 |

35g.cm2 |

| Weight |

0.21kgs |

0.21kgs |

0.24kgs |

| Length |

36.5mm |

36.5mm |

53mm |

| Connection |

P |

P |

P

|

General Specifications Item Specifications

- Step Angle Accuracy ±5%

- Resistance Accuracy ±10%

- Inductance Accuracy ±20%

- Temperature Rise 80℃ Max

- Ambient Temperature -20℃ ~ +50℃

- Insulation Resistance 100MΩ Min.500V DC

- Dielectric Strength 500V AC 1 minute

Applications of Stepper Motors

Stepper motors are diverse in their uses, but some of the most common include:

- 3D printing equipment

- Textile machines

- Printing presses

- Gaming machines

- Medical imaging machinery

- Small robotics

- CNC milling machines

- Welding equipment

How to overcome the vibration and noises of 2-phase hybrid stepper motor when rotating at low velocity?

The vibration and noise of the stepper motor rotating at low velocity its the intrinsic defects, which can be generally overcome by adopting following schemes:

1 1. If the stepper motor works at resonance region, the resonance region can be evaded by changing mechanical transmissions such as velocity ratio.

2. Use subdivided driver, which is the most common and simple method.

3. Replace for the stepper motor with smaller stepping angle, like 3-phase or 5-phase stepper motor.

4. Replace for AC servo motor, which can nearly overcome vibration and noise, but the cost is quite high.

5 Add magnetic damper to the shaft of motor, such product has been available in the market, but the mechanical structure is changed a lot.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!