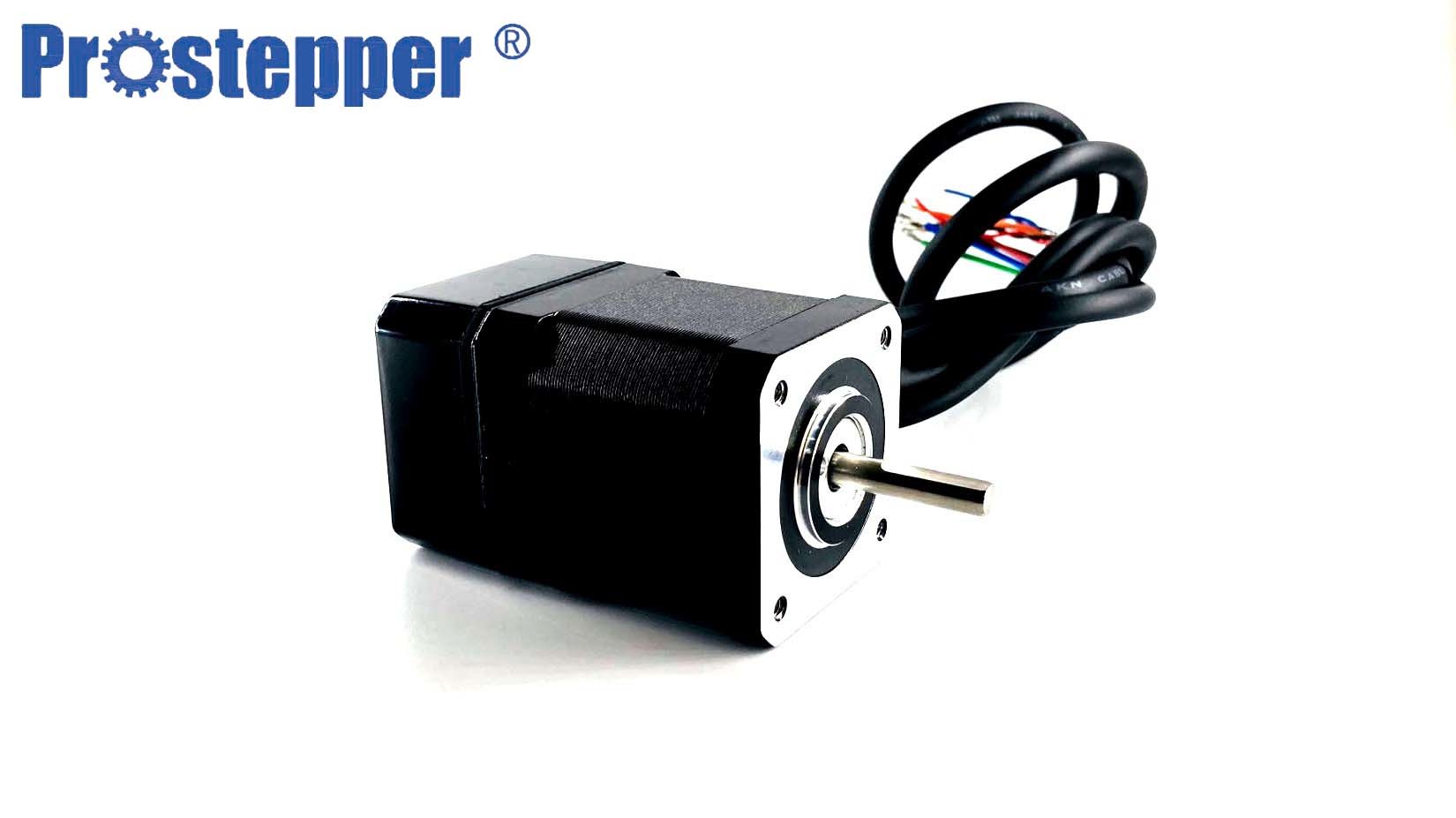

Stepper Motor Two Phase Hybrid Standard Type Nema34 1.8 degree stepper motor Black for robot

Product description

1. Online testing of technical parameters to ensure the consistency of data product parameters

2. Electromagnetic furnace optimization design, lift torque, reduce temperature rise, so that the motor running smoothly

3. Online testing of technical parameters to ensure the consistency of data product parameters

4. The material is selected from well-known manufacturers at home and abroad. The advantages are light weight, good heat dissipation performance, good thermal conductivity, die-casting, good plasticity, higher elongation than iron, low noise, good motion stability, the disadvantages are high price, low hardness

5. Material quality: The coat is 304 stainless steel, the water jacket is the high compression casting aluminum tube, the red copper coil.

6. Mechanical size 100% meet the requirements, to ensure that there is no greater error in the use process

Specifications

| Mode No |

PST28H251-4P10 |

PST28H251-4P15 |

| Holding Torque |

0.14 N.m |

0.14 N.m |

| Related Current |

1A/Phase |

1.5A/Phase |

| Resistance |

9.9Ω /Phase |

3.5Ω /Phase |

| Inductance |

6.7MH/Phase |

3.1MH/Phase |

| Inertia |

18 g.cm2 |

18 g.cm2 |

| Weight |

0.2kgs |

0.2kgs |

| Length |

51mm |

51mm |

| Connection |

P |

P |

Speed/Torque Characteristics(Reference Value)

Outline(Unit:mm)

Applications:

Used for robots stepper motor,

electronic automatic equipment stepping motor,

medical instrument stepping motor,

advertising instrument stepper motor

Special application requirements of bearing. Bad working environment

ENVIRONMENTAL REQUIREMENTS

Frost and snow, dust environment

High temperature, high humidity, condensation. Long time working

Stepper Motor Control by Varying Clock Pulses

Stepper motor control circuit is a simple and low-cost circuit, mainly used in low power applications. The circuit is shown in the figure,

A stepper motor is an electromechanical device it converts electrical power into mechanical power. Also, it is a brushless, synchronous electric motor that can divide a full rotation into an expansive number of steps. The motor’s position can be controlled accurately without any feedback mechanism, as long as the motor is carefully sized to the application. Stepper motors are similar to switched reluctance motors.

The stepper motor uses the theory of operation for magnets to make the motor shaft turn a precise distance when a pulse of electricity is provided. The stator has eight poles, and the rotor has six poles. The rotor will require 24 pulses of electricity to move the 24 steps to make one complete revolution. Another way to say this is that the rotor will move precisely 15° for each pulse of electricity that the motor receives.

The Advantages of Stepper Motors

Not every application will benefit from a stepper motor, but in the right environment stepper motors can be ideal. First, stepper motors have full torque at standstill, and the rotation angle of the motor is proportional to the input pulse. Essentially, stepper motors offer excellent speed control, precise positioning, and repeatability of movement.

Additionally, stepper motors are highly reliable since there are no contact brushes in the motor. This minimizes mechanical failure and maximizes the operation lifespan of the motor. These motors can be used in a wide range of environments, as many different rotational speeds can be achieved because the speed is proportional to the frequency of pulse inputs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!