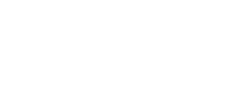

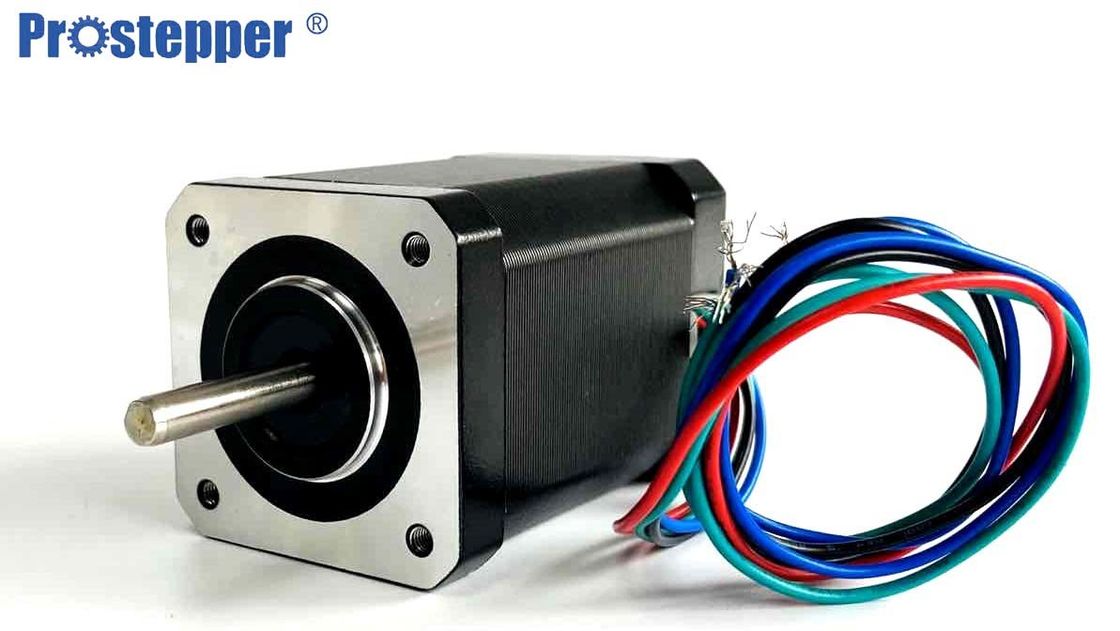

NEMA23 2 phase stepping motor 57mm 1.8 degree hybrid stepper motor

Description of NEMA23 hybrid stepper motor

1. Accurate position Control

The angular displacement of the stepping motor can be precise controlled by the number of electrical pulses.Angle accuracy can be controlled within ±0.09°without any feedback devices.

2. Longer Life

Stepping motor is a mechanical structure,which does not need be changed by electric brush or Hall sensor,thus reducing the probability and increasing the motor life.Stepping motor life usually determined by the life of the bearing.

3. Stepper motors are economical, accurate, and easy to control, and they can operate reliably in a variety of environments (depending on the level of protection IP chosen) preferably in machines with additional enclosures or in clean environments

4. Accurate Speed Control

The rotational speed of the stepping motor can be precisely controlled ,By controlling the frequency of the electric pulse.

Hybrid stepper motor's specifications

- Stepping Accuracy: ± 5%

- Resistance Accuracy: ± 10%

- Inductance Accuracy: ± 20%

- Temperature Rise: 80°C Max.

- Ambient Temperature: -20°C ... +50°C

- Insulation Resistance: 100MOhm min. 500V DC

- Withstand: 500V AC, 1 Minute

| Mode No |

PST57H265-4P20 |

PST57H265-4P30

|

PST57H265-4L40 |

| Holding Torque |

1.7N.m |

| Related Current |

2A/Phase |

3A/Phase |

4A/Phase |

| Resistance |

2 Ω/Phase |

0.9Ω /Phase |

0.5Ω/Phase |

| Inductance |

6MH/Phase |

2.7MH/Phase |

1.6MH/Phase |

| Inertia |

280g.cm2 |

| Weight |

0.72kgs |

| Length |

55.5mm |

| Connection |

P |

| Mode No |

PST57H276-4P30 |

PST57H276-4L40

|

PST57H276-4L50 |

| Holding Torque |

2N.m |

| Related Current |

3A/Phase |

4A/Phase |

5A/Phase |

| Resistance |

1.1Ω/Phase |

0.65Ω /Phase |

0.37Ω/Phase |

| Inductance |

4.2MH/Phase |

2.35MH/Phase |

1.8MH/Phase |

| Inertia |

480g.cm2 |

| Weight |

1.1kgs |

| Length |

76.5mm |

| Connection |

P |

L |

Applications of 1.8 degree Stepper Motor

Stepper motors are diverse in their uses, but some of the most common include:

- 3D printing equipment

- Textile machines

- Printing presses

- Gaming machines

- Medical imaging machinery

- Small robotics

- CNC milling machines

- Welding equipment

Custom Shaft & Mounting Details:

All motors can be supplied with single or double ended shaft to customer request shaft length and other dimensions can also be modified on demand.

Number of Leads:

All motors can be supplied with 4, 5, 6 or 8 leads and if required a connector can be provided on our motors to customer request

Winding code:

Since each customer request can be different, we list only our standard products in this catalogue. However, we will be happy to quote other variants to your request.

Holding Torque:

Holding torque is measured with two phases supplied at the rated current. The enclosed technical specifications are therefore typical.

(On customer request for special shaft, leads, fixings, etc. We will provide you with a unique product code/identifier)

The winding on this article is a 4 Wire Bipolar.

0.9° and 1.8° Hybrid Stepper Motors

1.8° Step Angle,The motors are directly compatible with the stepper motor drive boards and also drive either motor (if required) in the half step mode i.e. 0.9° per step resulting in higher resolution, greater performance stability and faster stepping rates. Direction, velocity, acceleration/deceleration can be controlled by a stepper motor controller.,Applying the correct electrical pulse sequence to the windings of the stepper motor results in a 1.8° step angle rotation of the spindle (i.e. 200 steps per revolution). When correctly loaded and driven these motors will produce discrete output steps. The number of steps and speed of rotation are determined by the number of pulses and frequency of the input signal. This provides an ideal method for speed and position control. The motors are directly compatible with stepper motor drive boards.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!