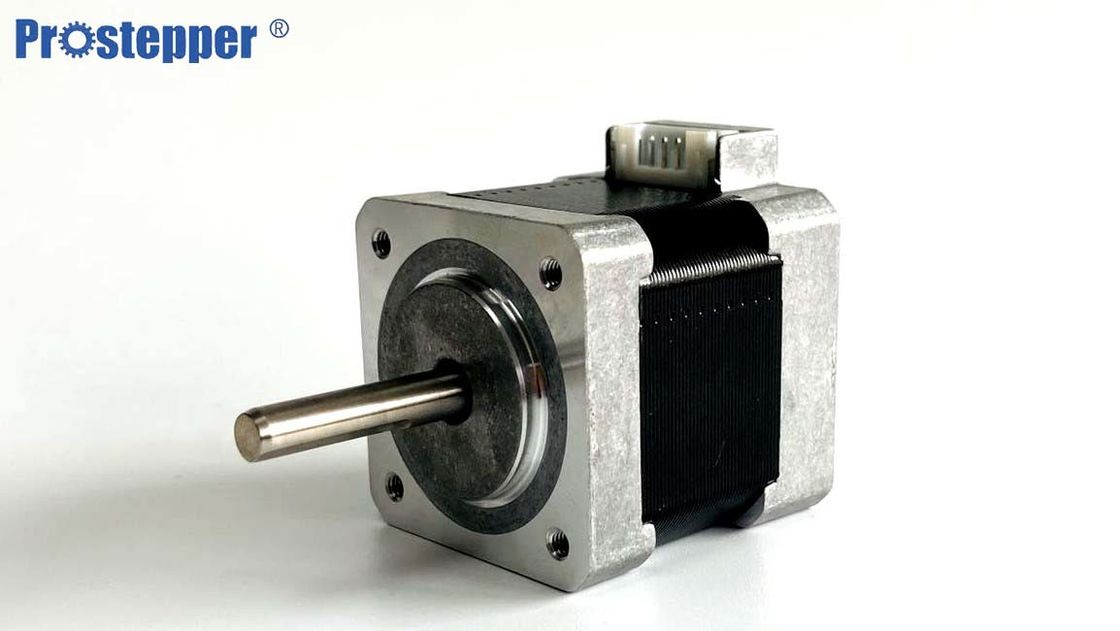

2-Phase Standard Type NEMA14 Bi-Polar stepper motor 35mm 0.18N.m

1. Accurate position Control

The angular displacement of the stepping motor can be precise controlled by the number of electrical pulses.Angle accuracy can be controlled within ±0.09°without any feedback devices.

2. Longer Life

Stepping motor is a mechanical structure,which does not need be changed by electric brush or Hall sensor,thus reducing the probability and increasing the motor life.

3. Automatic machine operation, stable automatic work, high processing efficiency.

4. Online testing of technical parameters to ensure the consistency of data product parameters

5. Electromagnetic furnace optimization design, lift torque, reduce temperature rise, so that the motor running smoothly

Specifications

| Mode No |

PST35H226-4P10 |

PST35H226-4P15

|

| Holding Torque |

0.07N.m |

0.07N.m |

| Related Current |

1A/Phase |

1.5A/Phase |

| Resistance |

3.1Ω /Phase |

1.4Ω /Phase |

| Inductance |

2.2MH/Phase |

0.9MH/Phase |

| Inertia |

12 g.cm2 |

12 g.cm2 |

| Weight |

0.15kgs |

0.15kgs |

| Length |

26mm |

26mm |

| Connection |

P |

P |

Note

The winding on this article is a 4 Wire Bipolar.

0.9° and 1.8° Hybrid Stepper Motors

1.8° Step Angle,The motors are directly compatible with the stepper motor drive boards and also drive either motor (if required) in the half step mode i.e. 0.9° per step resulting in higher resolution, greater performance stability and faster stepping rates. Direction, velocity, acceleration/deceleration can be controlled by a stepper motor controller.,Applying the correct electrical pulse sequence to the windings of the stepper motor results in a 1.8° step angle rotation of the spindle (i.e. 200 steps per revolution). When correctly loaded and driven these motors will produce discrete output steps. The number of steps and speed of rotation are determined by the number of pulses and frequency of the input signal. This provides an ideal method for speed and position control. The motors are directly compatible with stepper motor drive boards.,

Applications include:

- Robotics

- Paper feed mechanisms

- Teletype printers

- Small machine tools

- Computer peripherals

- X-Y plotters

Tips: How to overcome the vibration and noises of 2-phase hybrid stepper motor when rotating at low velocity?

The vibration and noise of the stepper motor rotating at low velocity its the intrinsic defects, which can be generally overcome by adopting following schemes:

1. If the stepper motor works at resonance region, the resonance region can be evaded by changing mechanical transmissions such as ve locity ratio.

2 Use subdivided driver, which is the most common and simple method.

3 Replace for the stepper motor with smaller stepping angle, like 3-phase or 5-phase stepper motor.

4. Replace for AC servo motor, which can nearly overcome vibration and noise, but the cost is quite high.

5. Add magnetic damper to the shaft of motor, such product has been available in the market, but the mechanical structure is changed a lot.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!